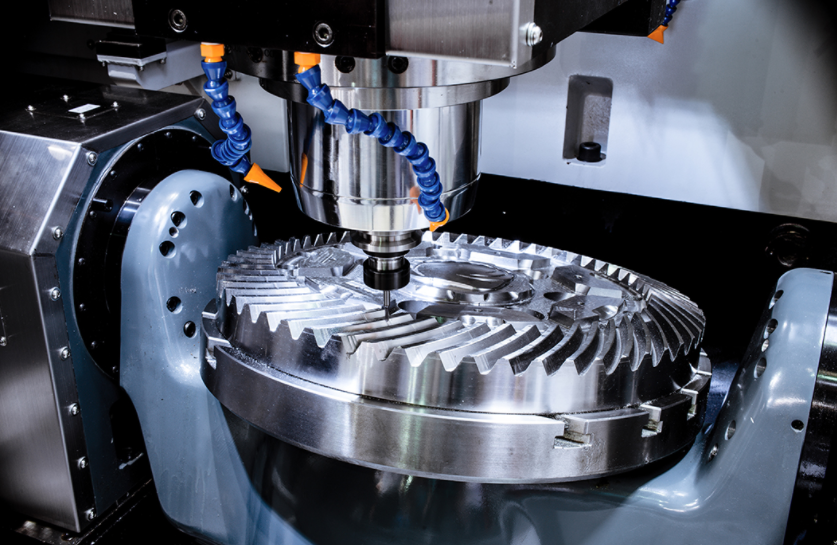

Formerly, the entire process took place on complex machinery that was hard to operate. As the machines had a multiaxis foundation, each axis needed individual control through levers supported by cam plates. These cam plates grant you control over the tooling device, the table designated for securing and rotating the part undergoing manufacture. As these machines were of considerable size, it took lots of time, effort, and skill to keep production running.

However, the invention of CNC machining has made it more effortless to manufacture more complex parts, as the execution steps are now at a minimum.

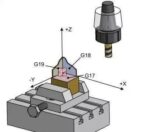

The three main elements of multiaxis machining include:

- The dynamic capacities of the machine, including the orientation of the axis, speed of the spindle, and revolution

- The CNC driving mechanism is the second component, consisting of the parts active during the machine’s movements. These may include the ball screws, speedy cross operations, servo-motors, and position monitoring.

- Lastly, the CNC controller, which happens to control the information transfer and storage and preparing the input data for command execution.

Types of Multiaxis CNC Milling Machines

The three most common CNC multiaxis machining are as follows.

3-Axis CNC machining

This multiaxis machining is a step up from traditional rotary filing. While the workpiece is in a fixed location, the cutting equipment moves around the X, Y, and Z axes. The X-axis runs parallel to the lathe table, the Y-axis lines up in the front/back direction, and the Z-axis has a marking from the spindle that drops from the top.

4-Axis CNC Machining

The 4-axis CNC machine works similarly to its 3-axis predecessor. The feed stays steady while the cutting tool operates to remove unwanted material, forming the targeted part.

As the name implies, this multiaxis machining incorporates the fourth axis alongside the standard X, Y, and Z planes. Rotation along the X-axis, which produces the fourth plane, the A-axis, provides this additional mobility. However, cutting vertically along the B-axis is also possible.

5-Axis CNC Machining

The X, Y, and Z axes are comparable to those of a 3-axis machine in this design. The table then revolves along the A-axis in the same way as it rotates along the 4-axis. However, 5-axis machining includes rotating at the table’s joint, accompanied by rotation along the C-axis, making up the fifth motion unique in this multiaxis operation. As a result, the machine is capable of producing remarkably meticulous parts.

Comparison of 3-Axis and 5-Axis CNC Machining

The more traditional 3-Axis machining

One of the most extensively employed methods for producing mechanical parts is 3-axis machining. It’s a straightforward procedure that involves utilizing traditional machining equipment such as a milling machine, which allows material processing on three axes. The cutting tool then separates shavings that correspond to the flat surface’s axis. It’s ideal for items that aren’t too deep, but it has heavy limitations for dealing with cavity-containing components. The process can therefore become quite labor-intensive, resulting in a somewhat ordinary finish.

The more advanced 5-Axis CNC machining

5-axis machining, as the name suggests, employs a tool that travels in five distinct directions, corresponding to the three linear axes X, Y, and Z, plus two additional axes, A and B, around which the machine revolves. The part may be accessible from all angles and worked from all five sides in a single process with this setup.

Unlike 3-axis machining, this method is ideal for more extensive pieces composed of sturdier materials, and the use of shorter cutting tools ensures a high level of accuracy. Moreover, there is an increase in machining rate, with a simultaneous decrease in tool vibrations.

Moving 3-Axis and 4-Axis to 5-Axis Machining

If you’re still using 3-axis or 4-axis machining to get things done, now might be the time to upgrade.

5-axis machining has unrivaled efficiency and precision CNC processing, and the workpiece may be complete in a single clamping operation. It may also help process advanced designs like auto components and aviation structural pieces.

The following are its crowning features.

Decreased manufacturing time

5-axis machining involves a cutter to keep the intricate design processing surface upright, which may drastically save processing time. This machining concept may also apply to side milling with an inclined surface, which can avoid rib-like streaks created by the ball cutting tool. Apart from saving time, this also eradicates the need to clean the part’s surface.

Precision development

Due to the lesser execution steps needed, there is a significant accuracy enhancement. Any extra process would only increase the chances of error, which you don’t have to worry about in 5-axis CNC machining.

Higher quality surface finishing

In 5-axis machines, the materials are relatively closer to the cutting tools. The last two axes (A and B) allow for the use of short-cutting tools that do not shake quite so much, resulting in a high-quality surface finish.

These machines can also effortlessly cut remarkably detailed shapes, which would usually need additional arrangements. This capability is thanks to various production angles.

Efficiency improvement

5-axis machining may significantly minimize component machining time. It features a wide range of spindle speeds and feed rates. These characteristics allow it to cut tremendous amounts of material quickly.

The quick motion and placement of 5-axis machining increase production efficiency and precision while reducing the operational time window for semi-finished materials.

Conclusions

CNC machining has found its way into nearly every industry, including industry design, aerospace, automotive, medical businesses and so on.

Right now to find a nearby CNC machining for your design is very easy since we entered into a digital world, information are very easy to reach. But to find a reliable CNC machining company online, you need to do some work before machining. Price, time, and quality always is the key, RapidDirect, is a online CNC machining company avail with 3, 4, and 5 axis CNC machining that provides manufacturing support for prototype designs and product generation. Simply upload your design files to get instant quotes. Keep in mind, employ different multiaxis for different precision degree, its price is vary.